Hot Mill Roll Grinding Case Study Advanced Hot Mill Roll Grinding Technology Delivers Unheard of Savings

Challenge:

A leading hot mill roll grinding facility was challenged to reduce their overall cost of grinding while maintaining aggressive roll processing levels. The company has tested other products that have shown longer life, but none of these wheels allowed them to achieve desired cycle times or effectively grind harder to grind materials like CPC or HSS.

Solution:

To address this need, the Weiler Abrasives team developed a grinding wheel like no other. We utilized an advanced phenolic resin technology paired with a proprietary blend of cutting-edge ceramic abrasive and next-generation engineered aluminum oxide grain. This unique design resulted in a wheel that was easy to work with on all materials, met their cycle time demands, all while showing an impressive improvement in life.

Result:

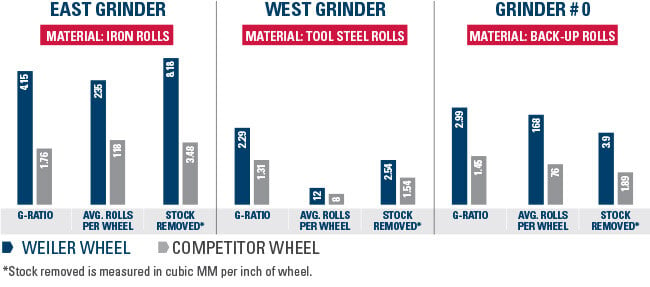

Weiler’s Roll Grinding Technology allowed the customer to maintain very aggressive cycle times and process all roll types without creating chatter or feed lines. As an added benefit, this wheel was easy to work with requiring little to no parameter changes to process rolls. Utilizing the Weiler Process Solutions tool, the Weiler team was able to document best practices and design a wheel that increased G-RATIO (wheel life) by 112% and decreased wheel changes by 50%. Those changes ultimately led to a total annual cost savings of $229,134.

112% Increase

50% Decrease

$229,134/year

Related Resources

Contact Us For Next Steps:

Call Weiler's Customer Experience Team at 800.835.9999. Our Application Engineers are available 8:30am to 5pm EST, Monday - Friday.

Or use our Application Assistance Form below and one of our Engineers will recommend a process or the best product to solve your problem at the lowest possible end-use cost.