Rail Construction Case Study Weiler Delivers Rail Construction Company Longer Product Life, Cost Savings

Challenge:

A leading rail infrastructure and superstructure construction company located in Spain, specializes in the construction of conventional and high-speed railway lines. Gas saw cutting wheels are used in new track laying and maintenance. With an estimated annual usage of 7,200 wheels, the company was looking to increase productivity and reduce abrasives spend.

Solution:

Weiler Application Experts visited the construction site and tested the Tiger Zirc 16" x 1/8" rail cutting wheel against the comparable competitive wheel. Both wheels were tested using a Husqvarna K1260 on 140 cm rail. After extensive testing, the Weiler Tiger Zirc wheel repeatedly cut faster, made cleaner cuts, and made 50% more cuts than the incumbent wheel.

Result:

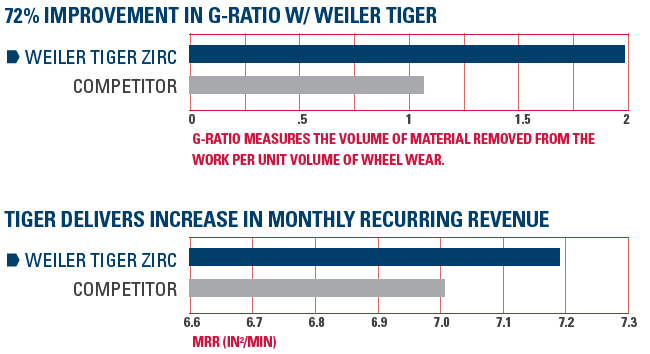

The Weiler Tiger Zirc wheel outperformed the competitive wheel in both metal removal rate and G-Ratio. The cost/performance improvement showed by the Weiler Tiger Zirc wheel will show the customer an estimated annual consumable saving of $54,000. In addition to these savings, the customer will realize productivity savings from faster cut times and an estimated 33% reduction in annual wheel changes.

#58029 Tiger Zirc 16" x 1/8" Cutting Wheels

50% Longer

$54,000/year

Related Resources

Contact Us For Next Steps:

Call Weiler's Customer Experience Team at 800.835.9999. Our Application Engineers are available 8:30am to 5pm EST, Monday - Friday.

Or use our Application Assistance Form below and one of our Engineers will recommend a process or the best product to solve your problem at the lowest possible end-use cost.