Tiger 2.0

Metal Grinding and Cut Off Wheels Help Cut Through the Barriers Between You and Your Best Work

Introducing Tiger 2.0 - An evolution in abrasives technology

Our new metal grinding and cut off wheels are designed to be more than just a better product. They were created to help you do your best work.

Cut Through Inefficiency

Tiger 2.0’s unique formulation offers industry-leading cut rates while lasting up to 30% longer. And its first to market, Optimum Use Line ensures you get more done with less.

Cut Through Safety Issues

Tiger 2.0 delivers predictable, smooth cutting and grinding, making the work safer. And it now has a QR code directly on the wheel, so operators can access crucial safety information right where – and when – they need it.

Cut Through labor shortages

Tiger 2.0 makes cutting and grinding easier, which means operators aren’t as worn out at the end of each shift. The unique formulation produces more consistent work from user to user, reducing training time and even re-work.

-

Faster and more efficient metal grinding and cutting

-

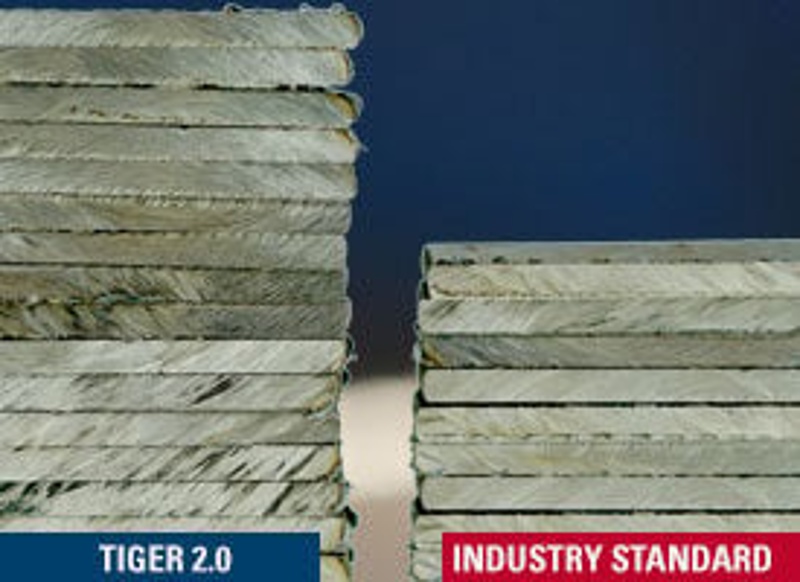

Lasts up to 40% longer than other grinding and cut off wheels

-

Patent-pending optimal use line for more productivity

-

Improved edge wear increases safety, operator experience, and wheel life

-

Predictable, smooth cutting and grinding for a safer workplace

-

QR code for crucial safety information at your fingertips

-

Consistent work from user to user, reducing training time and re-work

-

Easier on operators, reducing fatigue and labor shortages

Schedule an On-site Assessment

The first step to cutting through barriers is to schedule a free on-site assessment where Weiler experts will evaluate how our abrasives can help eliminate inefficiencies, safety issues, and labor shortages in your operation.

Our Approach To Improvement:

- On-Site Assessment

- Test Abrasives

- Measure Results

- Present Documented Cost & Time Savings

Product Innovations

Improves Safety

QR code provides quick access to important safety information.

Optimum Use Line

Using the wheel to its full life reduces change-overs, which helps users be more productive while reducing waste and abrasive spend.

Anti-chipping Technology

Advanced 2.0 bond formulation eliminates uneven edge wear and chipping, improving user experience and extending wheel life.

Fast Speed + Longer Life

Up to 40% longer wheel life reduces change-overs and delivers more cuts.

Value Added Programs

WCP

Think S.P.O.T

Related resources

View related resources for Tiger 2.0 Metal Grinding and Cut Off Wheels.