Precision, Quality, and On-Time Delivery are Non-Negotiables in Gear Manufacturing.

As industries like automotive, energy, and aerospace continue to grow and evolve, expectations for gear manufacturers are increasing. Weiler Abrasives can help. We provide industry-leading technology, expertise, and service to help improve your gear grinding operations now and in the future.

We are committed to providing value by:

Developing Tailored Solutions

Developing Tailored Solutions

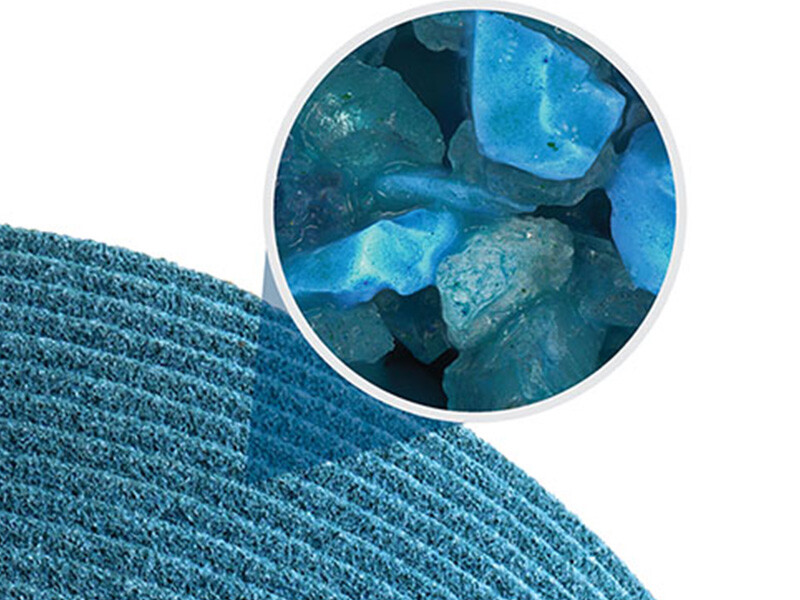

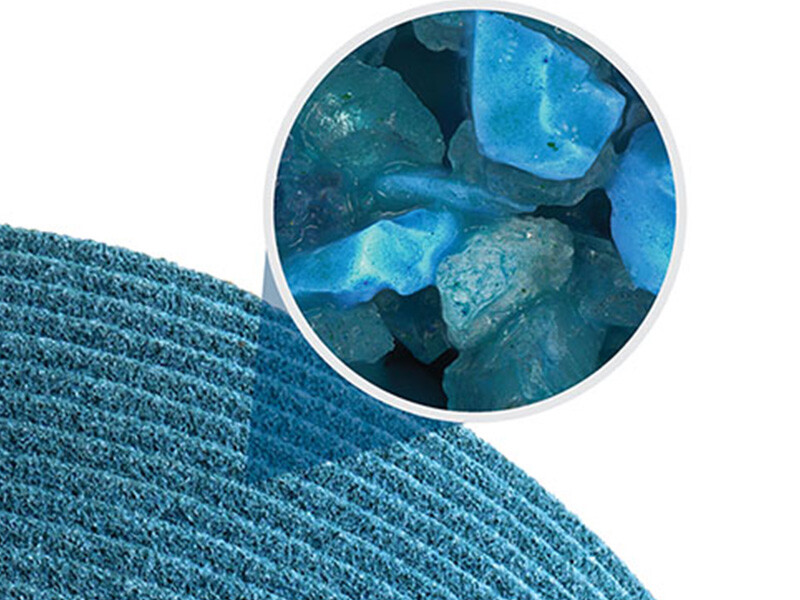

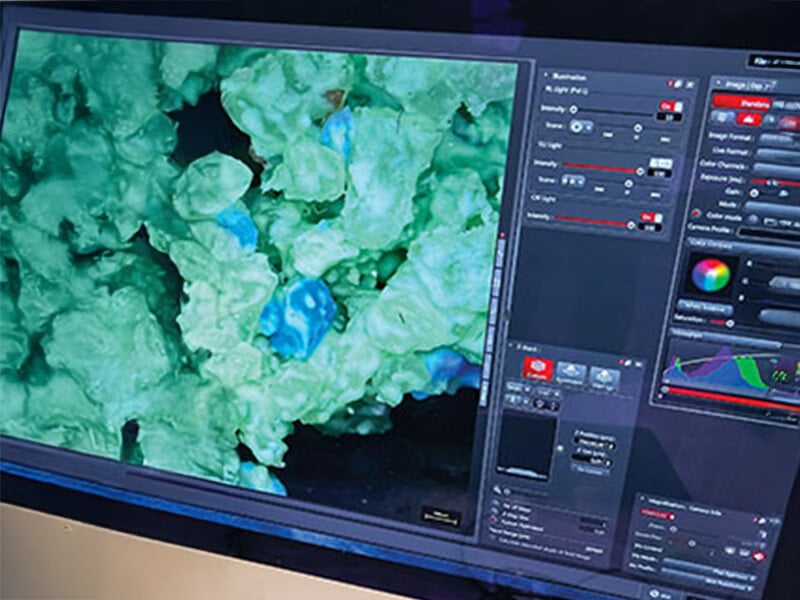

Our proprietary V59 bond system forms the foundation of our tailored solutions, addressing your needs with flexibility and precision.

Driving Technology Forward

Driving Technology Forward

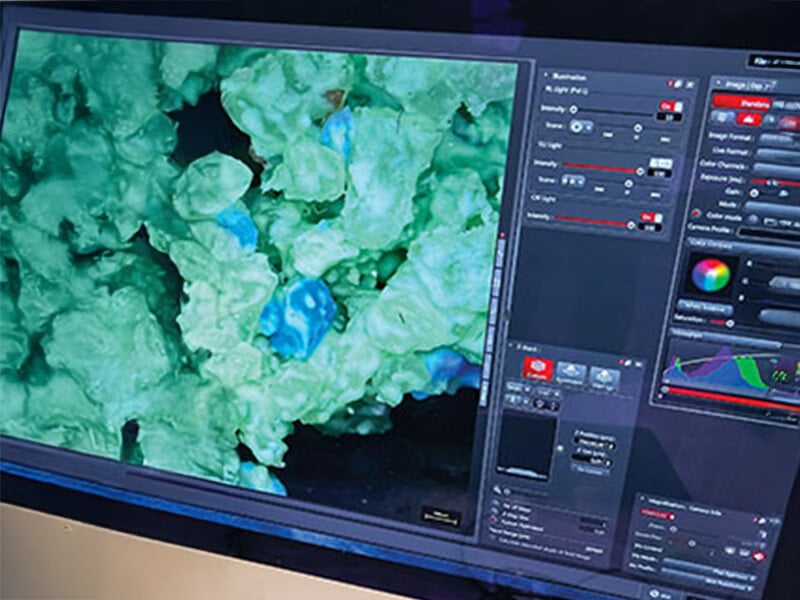

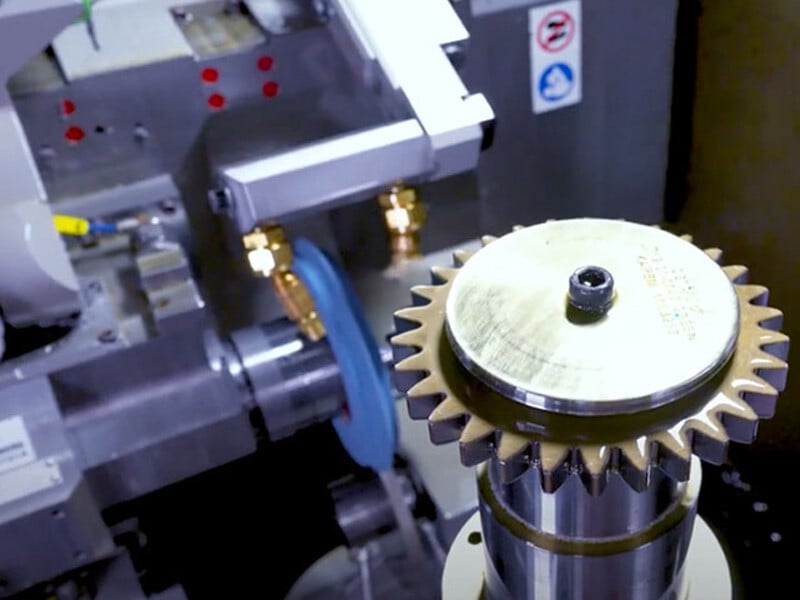

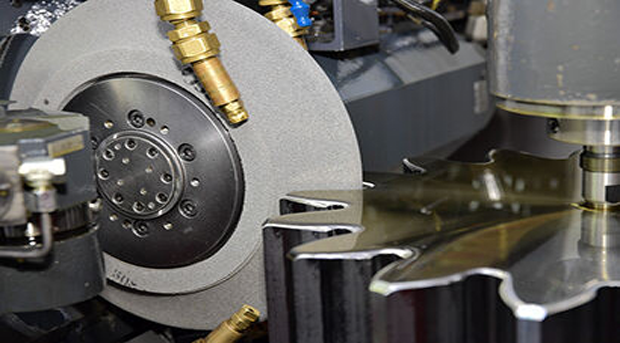

We leverage innovative thinking and advanced technologies to reduce dressing downtime and shorten grinding cycle times.

Implementing a Proven Process

Implementing a Proven Process

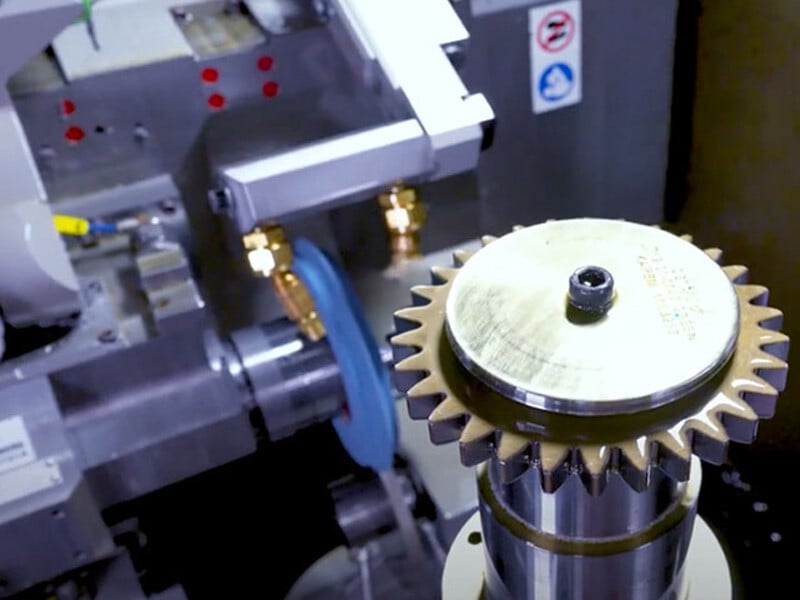

The Weiler Process Solutions (WPS) program is a comprehensive approach to improving gear grinding and other industrial grinding operations.

Delivering Continuous Improvement

Delivering Continuous Improvement

We're dedicated to finding improvements in productivity, efficiency, and cost savings for your grinding operations.

Developing Tailored Solutions

Developing Tailored Solutions

Our proprietary V59 bond system forms the foundation of our tailored solutions, addressing your needs with flexibility and precision.

Driving Technology Forward

Driving Technology Forward

We leverage innovative thinking and advanced technologies to reduce dressing downtime and shorten grinding cycle times.

Implementing a Proven Process

Implementing a Proven Process

The Weiler Process Solutions (WPS) program is a comprehensive approach to improving gear grinding and other industrial grinding operations.

Delivering Continuous Improvement

Delivering Continuous Improvement

We're dedicated to finding improvements in productivity, efficiency, and cost savings for your grinding operations.Precision Express: Delivering Continuous Improvement

Tired of long lead times and costly downtime? Precision Express delivers:

- Rapid Turnaround: Months-long lead times become days

- Expert Support: On-site troubleshooting and continuous improvement.

- Zero Downtime: Keep your operations running smoothly.

Discover how Precision Express can revolutionize your grinding operations.

Get StartedWeiler V59 Bond Technology Delivers Industry-Leading Results

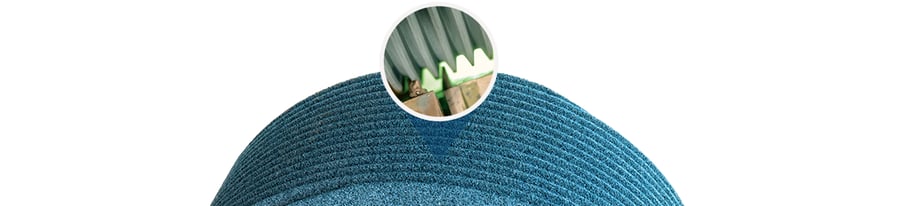

Superior Grain Retention

Advanced formulation holds abrasive grains longer for improved wheel performance.

Cool Cutting Technology

Dynamic porosity maximizes coolant and airflow for exceptionally cool grinding.

Long Wheel Life

Extended wheel life offers excellent profile retention and reduces the frequency of dressing cycles.

Increased Stock Removal

Achieve higher efficiency and productivity by reducing cycle times.

Consistent Grinding Results

From wheel to wheel, count on consistent grinding results every time for precise results.

Articles

Article: 4 Tips To Optimize Quality and Reduce Cycle Time in Gear Tooth Profile Grinding

Gear tooth profile grinding, also known as form grinding, is a finishing method used in gear manufacturing.

Article: Best Practices to Improve Results in Gear Deburring

All cutting and machining operations produce some type of burr or leave sharp edges on metal components.