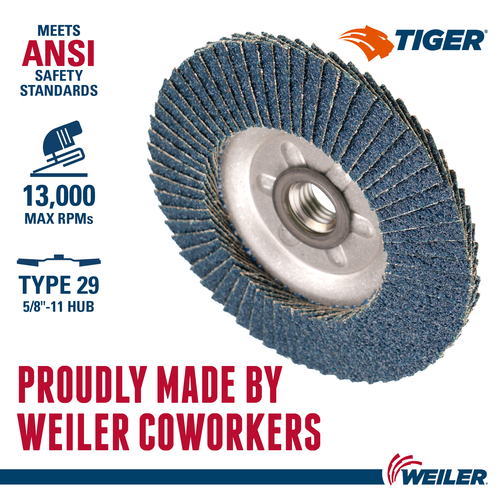

ITEM: 50518

4-1/2" Tiger Disc Abrasive Flap Disc, Conical (TY29), Aluminum Backing, 40Z, 5/8"-11 UNC Nut

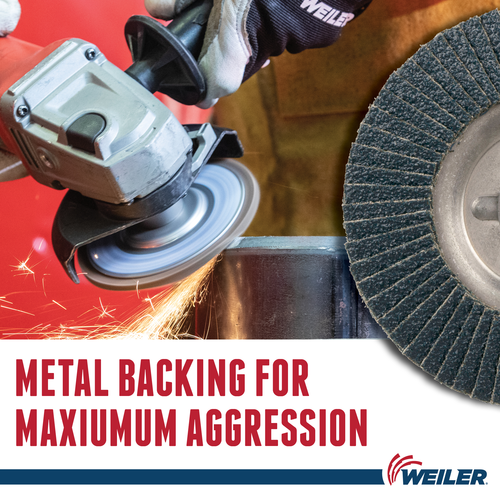

Tiger Aluminum Back 4.5 inch conical flap discs are the benchmark for the pipeline industry, providing rigid support for maximum aggression when grinding steel and stainless steel. These wheels are ideal for removing heavy pitting and resists rolling the pipe bevel ends prior to welding. The aluminum backing also prevents the disc from catching on the bevel when grinding. The type 29 conical disc shape maximizes surface contact when grinding between 15° – 35° for aggressive stock removal on flat surfaces while the 40 grit abrasive grain is best for edge beveling, chamfering, weld grinding, and blending with a right angle grinder. This disc offers a metal 5/8" - 11 nut that allows for quick changeovers and prevents the disc from sticking to the spindle.

Material Application

Grinding

Finishing

Compatible Tools

Right Angle Grinder

Features & Benefits

Aluminum backing provides rigid support for maximum aggression and is recyclable..

Self-sharpening zirconia alumina (ZA) grains hold up under high temperatures and extreme pressure..

Contaminant-free (contains less than 0.1% Fe, S, Cl)..

5/8" - 11 metal nut allows for quick spin-on, spin-off changeover and eliminates cross-threading or sticking to spindle due to heat build-up..

Best on carbon steel, structural steel, stainless steel, and cast iron..

Specifications

Grit

40

Color

Blue

Ro Hs

Compliant

Brand ID

WeilerTiger

Diameter

4-1/2 IN

Industry

Fabrication, Pipeline

Disc Type

Type 29

Grain Type

ZA

Application

Grinding, Finishing

Maximum RPM

13000

Performance

High-Performance

Flap Density

Standard Density

Product Type

Flap Disc - Tiger

ANSI Standard

B7.1

Commodity Code

6805 30 1000

Arbor Hole Size

5/8"-11 UNC

Compatible Tool

Right Angle Grinder

Item UPC Code

012382505189

Sales Unitof Measure

EA

Backing Plate Material

Aluminum

Standard Pack Quantity

10

Prop65Warning Description

WARNING Silica

Resources

Speak with an Expert

Weiler Abrasives is an industry leader and global manufacturer of surface conditioning solutions. We are eager to create a collaborative partnership to overcome your toughest cleaning, grinding, cutting, de-burring, and finishing challenges.