Optimal Cleaning in the Foundry Operation

From blending parting lines to grinding burnt sand castings, the foundry cleaning room presents productivity challenges that can often be a bottleneck in the foundry process. Having the right abrasives is critical — that’s why Weiler Abrasives offers a variety of solutions specifically for foundry applications. Our line of abrasives can help you address tough grinding and finishing jobs to decrease cycle times while gaining a quality finish.

We know the job of metal casting isn’t easy and neither is cleaning and finishing, so operators deserve products that are easy and safe to use. Better abrasives mean greater efficiency.

Ceramic Foundry Advantage

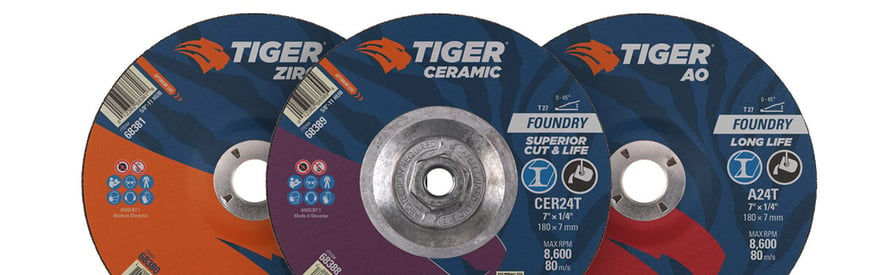

Weiler Abrasives is setting the standard for performance in the foundry process with its Tiger® Ceramic abrasives technology. Featuring an ultra-fine micro-structure that self-sharpens, these products provide ultra-fast grinding, high removal rates and a longer wheel life. Weiler Abrasives offers ceramic foundry abrasives in Type 11 cup grinding wheels and Type 27 grinding and combo wheels, as well as cones, plugs and snagging wheels.

Request A ConsultationType 27 Grinding Wheels

Tiger Ceramic has been specifically designed for tough metal foundry applications, offering superior cuts and long life. These depressed center wheels can remove up to 40% more material than competitive zirconia products, resulting in more uptime and fewer abrasives replacements.

Weiler Abrasives has also incorporated an advanced anti-chipping technology to improve operator safety in the foundry operation. It eliminates uneven edge breakage and chipping and reduces the chance of flying debris during grinding. The technology also lengthens wheel life and offers a reliable grinding edge, while a triple fiberglass reinforcement design further increases wheel strength.

Weiler Abrasives also offers the Tiger Type 27 grinding wheel in zirconia and aluminum oxide grain — both performance tiers, with the ceramic setting the highest standard.

Type 11 Flaring Cup Grinding Wheels

When compared to competitive zirconia cups, Weiler Abrasives industry-exclusive ceramic grain technology allow the Tiger Ceramic cup grinding wheels to cut up to 30% faster. This results in high metal removal and improved productivity in the foundry cleaning room, especially on hard-to-grind materials. A balanced cup design reduces vibration and operator fatigue.

Each cup wheel includes a Weiler Abrasives exclusive safety feature — an anchored hexagon nut that secures the cup in place, locking it to the tool. Operators can have peace of mind when working on the most challenging metal casting foundry jobs, knowing that the cup is secure and resists breakage. This zinc-plated nut also resists oxidation and compared to cups with standard metal backs, offers up to three times higher torque holding strength and withstands double speed burst test ratings.

Tiger cup wheels are also available in zirconia for fast metal removal, silicon carbide for burnt sand castings and alumina oxide grains for cast iron metal foundry applications.

Cones & Plugs

For use with straight grinders, Tiger cones and plugs provide an aggressive cut-rate from start to finish. They are ideal for ID cleaning, hole edge beveling, cleaning castings in hard-to-reach areas. Each cone and plug feature an anchored, heavy-duty steel hex nut to secure the abrasives to the grinder and improve operator safety.

Snagging Wheels

Tiger Type 1 portable snagging wheels for pneumatic straight grinders and high frequency electric straight grinders support heavy stock removal, rough beveling, and snagging. They are available in 3, 6- and 8-inch wheels with double fiberglass reinforcements to increase strength and resist chipping.

Weiler Abrasives offers the cones, plugs and snagging wheels for the foundry cleaning room including Tiger Ceramic, Tiger Zirc and Tiger AO. Each abrasive type and grain provide smooth, vibration-free operation to improve operator comfort and lessen fatigue. An open face design also provides aggressive cut-rate right out of the box.

Mounted Points

Ideal for cleaning IDs, complex geometries, hard-to-reach places and more, Tiger Zirc mounted points are available in a variety of shapes. They feature an engineered stem bonding for strength, stability and safety and have a dressed work surface, so operators don’t need to break them in.

Consumable Productivity Program:

This program allows Weiler Abrasives specialists to collect data on-site, evaluate abrasive use and offer recommendations for abrasives that optimize grinding and improve throughput.

SPOT Safety Training

Weiler Abrasives offers safety training based on SPOT (Speed & Size, Pressure, Orientation, Time) to help operators learn the proper and safe way to use abrasives.

Engineered Products & Custom Solutions

For challenging metal foundry applications, Weiler Abrasives can offer custom-engineered products or evaluations to provide solutions to difficult problems.

Our Commitment

The Weiler Abrasives team is committed to helping foundries like yours eliminate the bottleneck in the grinding process so you can increase production efficiency, meet customer expectations, and improve profitability. Schedule a consultation with an abrasives expert today and let's find your improvements.